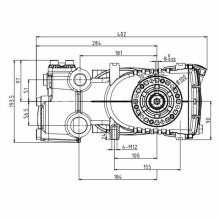

Custom Aluminum Machinery Die Casting Parts

| Payment Type: | T/T |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,FCA |

| Min. Order: | 4000 Piece/Pieces |

| Delivery Time: | 35 Days |

| Packaging: | carton, PE pallet, plastic pass box |

|---|---|

| Productivity: | 5000/MONTH |

| Brand: | NONE |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | NINGBO |

| Supply Ability: | 120000/MONTH |

| Certificate: | ISO/TS16949:2009 |

| HS Code: | 7616991090 |

| Port: | NINGBO,SHANGHAI |

Basic Info

Model No.: BL025

Click on the follow link to find out more information: https://www.bldiecasting.com/cnc-turning/

Company Info

- Company Name: NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY

- Representative: LIU CHENGZHI

- Product/Service: Die Casting , Precision Machining , Precision Casting , Pressure Casting , High Precision CNC Machining , Ferrous Metal

- Capital (Million US $): 1000000 RMB

- Year Established: 2001

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 3

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Guisi Industrial Zone, Luotuo Street, Zhenhai District,Ningbo,315206,China

- Contact Person: Mr. Ethan

- Tel: 86-0574-86556929

Premium Related Products

Other Products

Hot Products

Elevator Roller Guide Shoe (GDX01)Floor Drain, Stainless Steel PlolishingFolding Notebook Barbecue Charcoal GrillPrecision Custom Micro CNC Laser Cutting Metal PartsMailboxWkc 307 Customized Forged Carbon Steel Flange Pipe FittingCustom High Precision CNC Machined Anodized Aluminum PartsAluminum 6061/ 6063 CNC Machined Part with Bright Black AnodizingProfessional CNC Parts, Plastic and Metal/ Aluminium Parts Machining/ CNC Machining PartsSheet Metal Enclosure / Housing / CoverStainless Steel Pendant MarbleAluminum Casting and Die Casting PartSpare Parts of Spray Gun NozzleStamping Products / Sheet Metal FabricationSheet Metal of Laser Engraving Parts / Laser CuttingSheet Metal Stamping Parts