High Pressure Aluminum Die Casting Process Die Cast

Basic Info

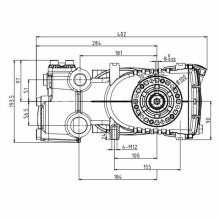

Model No.: WKC-41

Product Description

Model NO.: WKC-41 Die Casting Method: Precision Die Casting Machining: CNC Machining Surface Preparation: Oxygenation Tolerance Grade: 7 Certification: SGS, CE, RoHS, ISO 9001:2000, ISO 9001:2008, DIN CNC Machining or Not: CNC Machining Type: Broaching, Drilling, Etching / Chemical Machining Inspected: 100% Inspected Before Delivery Sampelling Time: Within 7 Days Surface Finishing: Anodizing, Polishing, Plating, Blacken Specification: SGS, ISO9001 HS Code: 84669300 Die Casting Machine Type: Cold Chamber Die Casting Machine Application: Electronic Accessories Material: Aluminum Pressure Chamber Structure: Horizontal Casting Surface Quality Level: 3 Name: High Pressure Aluminum Die Casting Process Die Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals Micro Machining or Not: Not Micro Machining Size: as Per Customer′s Requirments Bulk Lead Time: 20-50 Days Trademark: weldo Origin: Guangdong, Dong Guan high pressure aluminum die casting process die cast

Specification:

Technical Details

Why Choose us:

1. Fully Machining Services: Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service. 2.Various Machining Materials: Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect. 3.Various Finishes: Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts. 4.Quality Assurance : IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us. 5.Advantage: 1>.Non-standard/standard/OEM/ODM/customized service provided 2> No MOQ, no quantity limited 3 >Fast lead time 4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Related Products

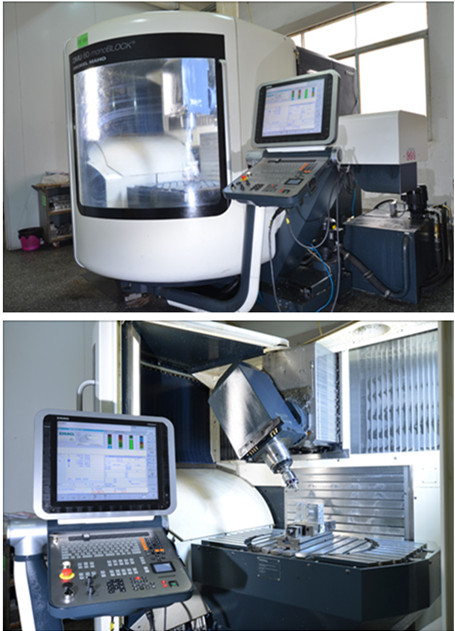

Factory Tour

After Service Welcome consult with us, we service: 1. Best Solution for your production 2. Fast delivery for your urgent order.

3.Sandy + 86 18680402057 Contact us if you need more details on Pressure Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pressure Die Casting、Aluminum Pressure Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specification:

| 1.Material | Aluminum, Brass, Bronze, Copper, Hardened Metals |

| 2.Tolerance | +/-0.05mm |

| 3.Finishing | anodizing,polishing,plating ,blacken ect |

| 4.Edges and holes | debarred |

| 5.Surfaces | free of scratches |

| 6.Material capabilities | aluminum, stainless steel, copper, plastic and more |

| 7.Various materials and finishing ways are available | |

| 8.Non-standard aluminum product | |

| 9.Material and finishing comply with RoHS Directive | |

| 10.Small orders are welcome | |

Technical Details

Technical Process | CNC machining, EDM W/C |

Dimension | Client's artwork is available |

Capability | Milling:Length,machining range up to 1100*600 mm |

Turning: Diameter 0.05mm~300mm ; Length 0.5mm ~ 750mm | |

Wire Cutting: machining range can up to 450*400*300mm | |

Precision | Turning and Milling:+/- 0.002mm(+/-0.000098 inch) |

Wire Cutting: +/- 0.002 mm (+/-0.000098 inch) |

Why Choose us:

1. Fully Machining Services: Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service. 2.Various Machining Materials: Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect. 3.Various Finishes: Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts. 4.Quality Assurance : IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us. 5.Advantage: 1>.Non-standard/standard/OEM/ODM/customized service provided 2> No MOQ, no quantity limited 3 >Fast lead time 4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Related Products

Factory Tour

After Service Welcome consult with us, we service: 1. Best Solution for your production 2. Fast delivery for your urgent order.

3.Sandy + 86 18680402057 Contact us if you need more details on Pressure Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pressure Die Casting、Aluminum Pressure Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Die Casting Parts

Premium Related Products

Other Products

Hot Products

Elevator Roller Guide Shoe (GDX01)Floor Drain, Stainless Steel PlolishingFolding Notebook Barbecue Charcoal GrillPrecision Custom Micro CNC Laser Cutting Metal PartsMailboxWkc 307 Customized Forged Carbon Steel Flange Pipe FittingCustom High Precision CNC Machined Anodized Aluminum PartsAluminum 6061/ 6063 CNC Machined Part with Bright Black AnodizingProfessional CNC Parts, Plastic and Metal/ Aluminium Parts Machining/ CNC Machining PartsSheet Metal Enclosure / Housing / CoverStainless Steel Pendant MarbleAluminum Casting and Die Casting PartSpare Parts of Spray Gun NozzleStamping Products / Sheet Metal FabricationSheet Metal of Laser Engraving Parts / Laser CuttingSheet Metal Stamping Parts