All Categories

- Sheet Metal Stamping

- Sheet Metal Fabricatio

- Laser Cutting Service

- Precision CNC Machinin

- Precision Casting Prod

- Heavy Welding & Machin

- Elevator, Elevator Par

- Laser Cutting Parts

- CNC Machining Parts

- CNC Turning Parts

- CNC Milling Parts

- Flange And Fittings

- Metal Stamping Parts

- Die Casting Parts

- Gear&Transmission

- Aluminum Profile

- Automation Machine

- OEM Mechanical Assembl

- More Products

Featured Products

POPULAR PRODUCTS

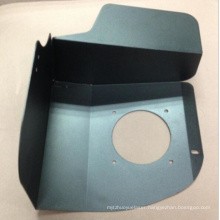

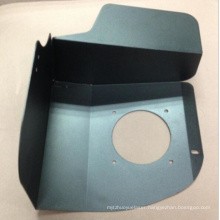

Sheet Metal Stamping Parts

Sheet Metal Stamping Parts Sheet Metal of Laser Engraving Parts / Laser Cutting

Sheet Metal of Laser Engraving Parts / Laser Cutting Stamping Products / Sheet Metal Fabrication

Stamping Products / Sheet Metal Fabrication Sheet Metal Stamping Parts

Sheet Metal Stamping Parts Stamping Parts (NLK-001)

Stamping Parts (NLK-001) Laser Cutting Part (NLK-L002)

Laser Cutting Part (NLK-L002) Stainless Steel 304 Wire Mesh

Stainless Steel 304 Wire Mesh Spare Parts of Spray Gun Nozzle

Spare Parts of Spray Gun Nozzle Laser Cutting Service (NLK-S-003)

Laser Cutting Service (NLK-S-003) Aluminum Casting and Die Casting Part

Aluminum Casting and Die Casting Part Spare Parts / Spray Gun Parts

Spare Parts / Spray Gun Parts Aluminum Casting

Aluminum Casting

Stainless Steel Toilet Paper Holder with Phone Shelf, Bathroom Tissue Holder Toilet Paper Roll Holder

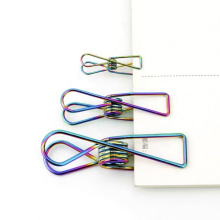

Stainless Steel Toilet Paper Holder with Phone Shelf, Bathroom Tissue Holder Toilet Paper Roll Holder 304 Stainless Steel Clothes Pegs, Three Size Clothes Line Hanger Clips

304 Stainless Steel Clothes Pegs, Three Size Clothes Line Hanger Clips Custom Aluminum Stainless Steel Coffee Tamper Handle Bar for Kitchen Accessories

Custom Aluminum Stainless Steel Coffee Tamper Handle Bar for Kitchen Accessories China Factory Custom High Polishing Small Pipe Fittings/ steel pipes/seamless stainless steel 304 tube for Furniture

China Factory Custom High Polishing Small Pipe Fittings/ steel pipes/seamless stainless steel 304 tube for Furniture China Factory Good Price Custom Die Cast Aluminum Housing with heat sink for 5G Devices

China Factory Good Price Custom Die Cast Aluminum Housing with heat sink for 5G Devices Customized cnc lathe made coffee machine gun, coffee tamper

Customized cnc lathe made coffee machine gun, coffee tamper Customized 51mm 58mm Stainless Steel Coffee Tamper

Customized 51mm 58mm Stainless Steel Coffee Tamper New Stainless Steel Coffee Tamper Machine Bar Kitchen Accessories

New Stainless Steel Coffee Tamper Machine Bar Kitchen Accessories Customized Black Powder Coat coffee tamper

Customized Black Powder Coat coffee tamper Customized LARGE BLACK POLISHED TOP HANDLE ESPRESSO COFFEE TAMPER Tamper

Customized LARGE BLACK POLISHED TOP HANDLE ESPRESSO COFFEE TAMPER Tamper ISO9001 pass handle aluminum base sus304 coffee tamper 58mm

ISO9001 pass handle aluminum base sus304 coffee tamper 58mm Customized CNC Stainless Steel Coffee Espresso Tamper with Flat Base

Customized CNC Stainless Steel Coffee Espresso Tamper with Flat Base